BioEconomy Marketplace

The Processes and Products of the US biomanufacturing community

Archive Featured Products:

Lygos - September 2023

Checkerspot - October 2023

KeyLeaf - November 2023

MangoMaterials - December 2023

September Featured Product:

Soltellus™

Soltellus™ polymer is sustainable, biodegradable, and water-soluble with applications in home care, agronomy, and water treatment.

October Featured Product:

Checkerspot® Cast PU Systems

Made with Checkerspot's renewable algae oil, Checkerspot® Cast PU enables customers to replace petroleum-based incumbent materials with a high-quality, biobased alternative. This product contains up to 70% bio-content.

Applications:

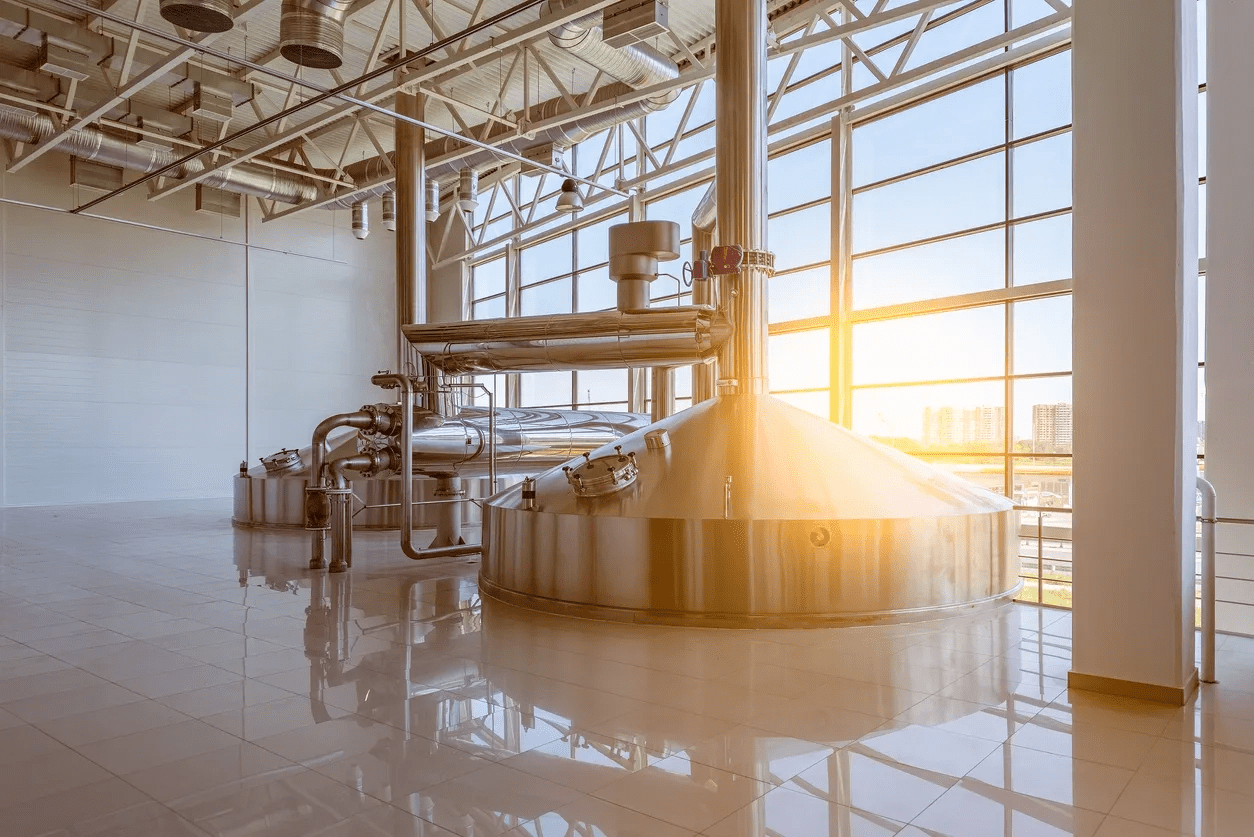

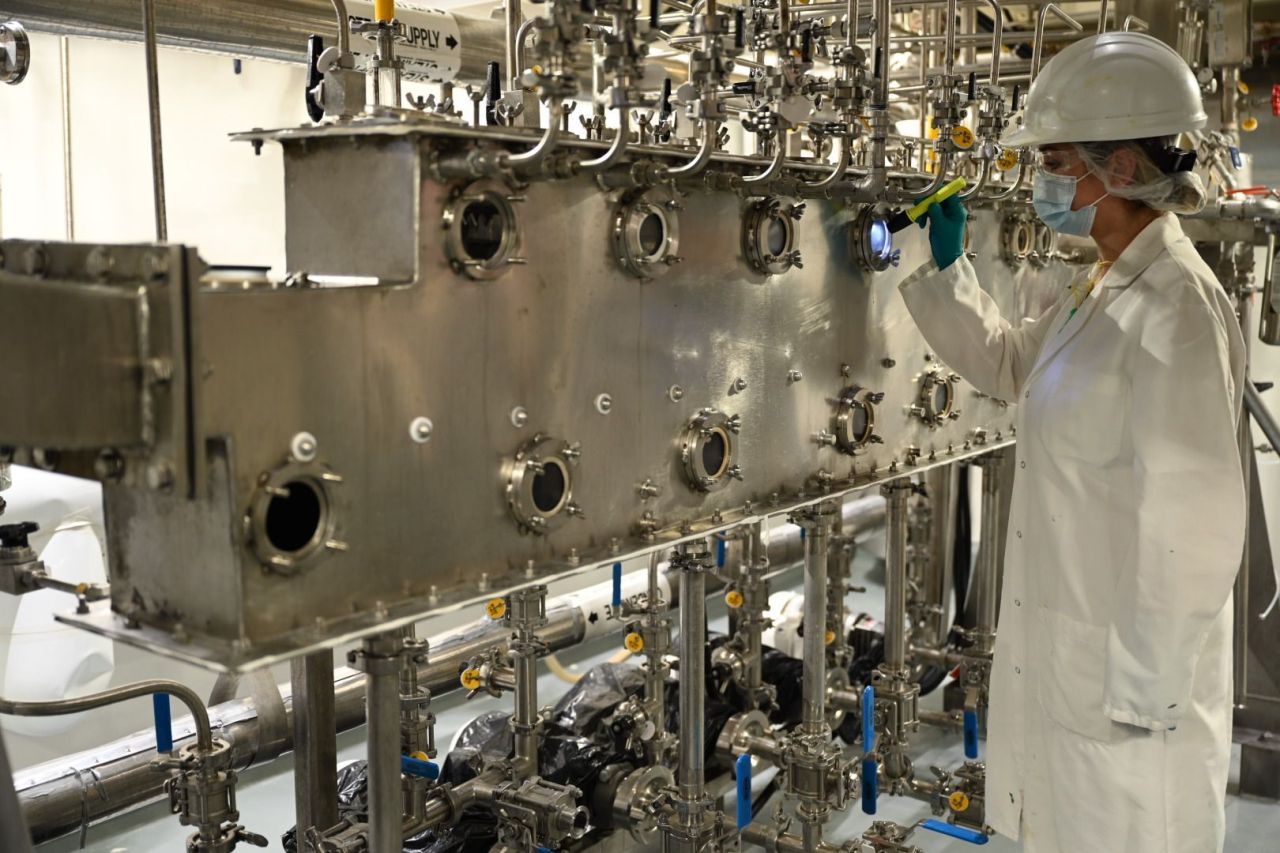

KeyLeaf Life Sciences

KeyLeaf is a leader in helping clients with downstream processing of their food, nutritional and cosmetic ingredients. KeyLeaf scientists and technical teams collaborate with companies to help with the extraction, separation, purification, and formulation of desired compounds from various streams of biomass.

Since 1991, the KeyLeaf site in Batavia, Illinois has been serving clients in the design, piloting and purification of oil and lipid specialty compounds. This facility has been recognized for its expertise in molecular high vacuum distillation (short-path and fractional). The Batavia facility operates under regular Good Manufacturing Practices (GMP), maintains food grade standards and follows food processing regulatory guidelines.

DSP services available:

December Feature:

About Mango Materials

Mango Materials, a California-based biomanufacturing company, produces biopolymer pellets made with polyhydroxyalkanoate (PHA). PHA is a biological byproduct of naturally occurring ancient bacteria. It can be melt-processed by third parties using similar methods to traditional polymers and manufactured into a variety of high-volume, environmentally friendly goods such as packaging, children’s toys, fibers, films, and molded consumer products.

Mango Materials has a unique way to make PHA. Using methane (a potent greenhouse gas) produced by wastewater treatment plants, the company feeds methane to bacteria that transform it into PHA. When products made from our PHA are disposed of after their useful life, they re-enter the naturally occurring carbon cycle.

YOPP® and YOPP+ PHA Pellets and Products